Lightweight Composite Gears and Torque Shafts

Showcasing our lightweight composite gears and torque shafts at Farnborough Air Show

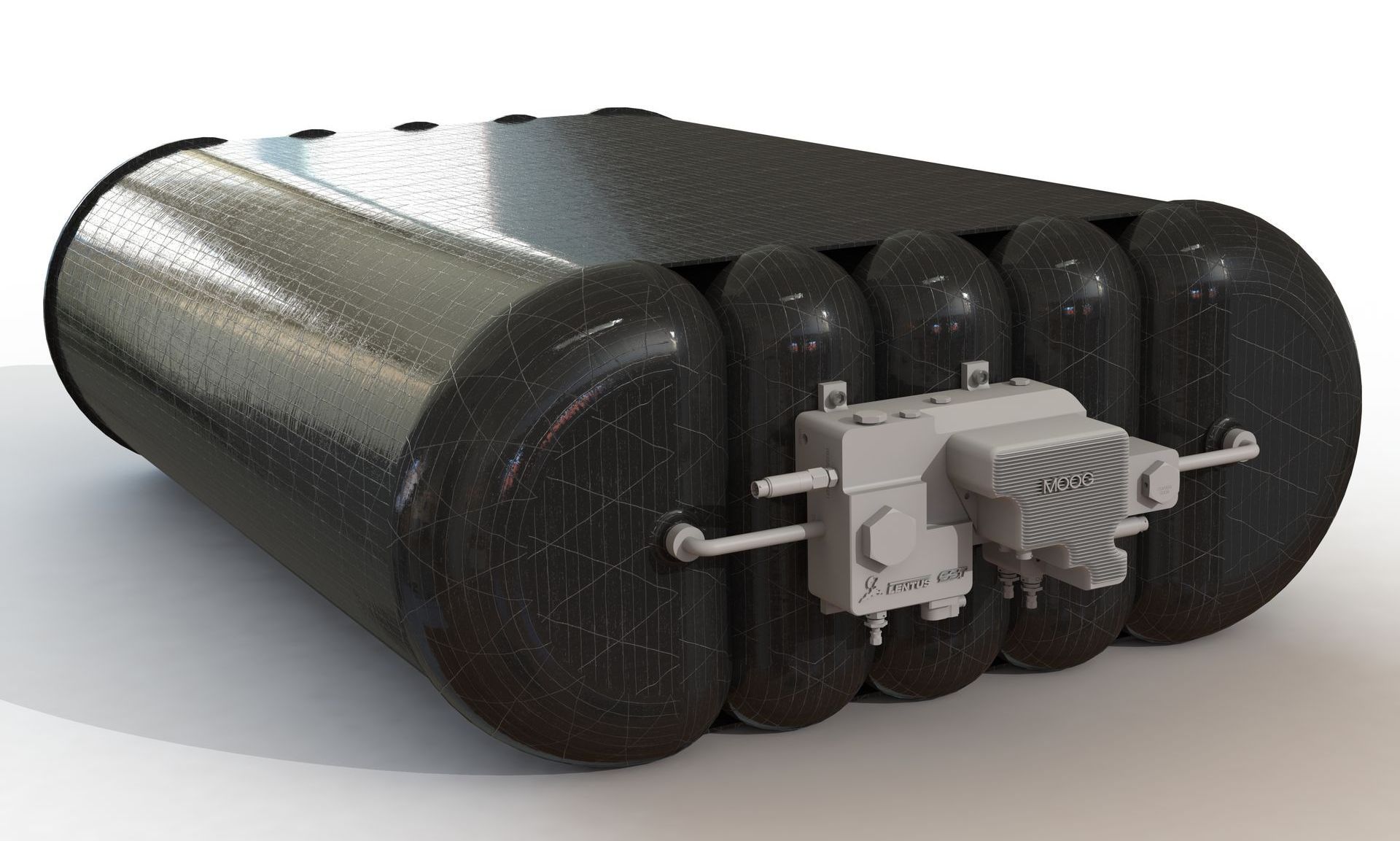

A leader in composite product design, manufacture and composite to metallic joining, Lentus Composites, part of the Polar Technology Group, has a mature composite torque shaft technology used in a variety of applications across aerospace, high performance automotive and advanced transportation applications. The team is now applying its expertise in metallic to composite joining to significantly reduce weight and inertia in Gear applications.

Lentus has demonstrated a weight saving of 40% by replacing the gear body and in some cases the shaft with a composite solution, joining of this body and shaft to the metallic gear interface is achieved using a novel and robust mechanical joining technique.

For more information at Farnborough International Airshow, please see the Polar Team in Hall 3 stand 3820 who will be happy to discuss your requirements.

UK Office:

Horizon Technology Park, Stanton Harcourt Rd, Eynsham OX29 4GF

Polar Technology Management Limited (Company Reg No. 07861070 Registered office: 67 Hightown Rd, Banbury, Oxfordshire OX16 9BE.)

Lentus Composites

Website Design by Warpspeed Web