About Us

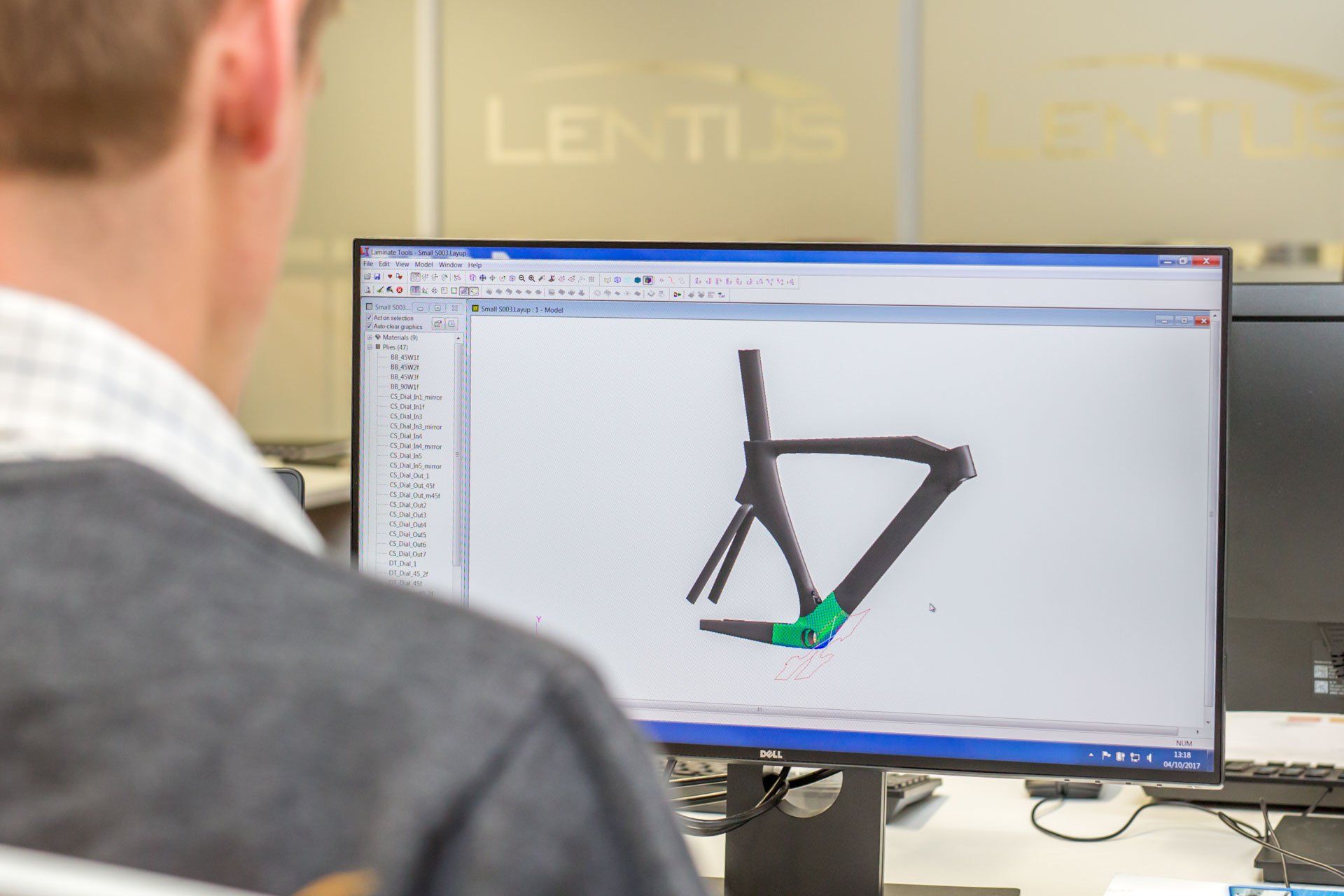

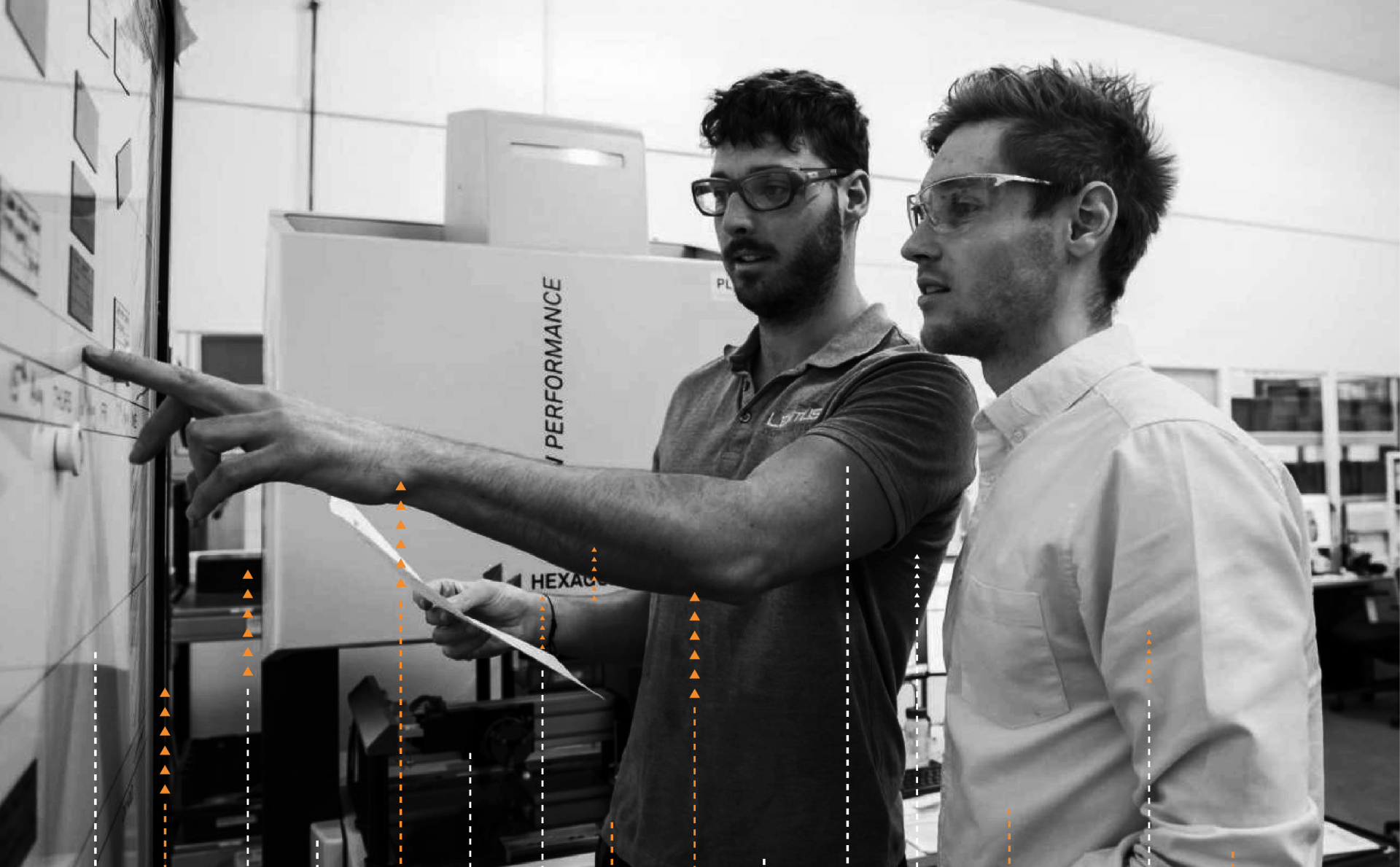

Lentus Composites is an engineering led manufacturer of composite products, assemblies and systems for a range of industry sectors. Lentus can design, analyse, produce prototypes, carry out qualification testing and put parts into low or high volume production.

Latest News

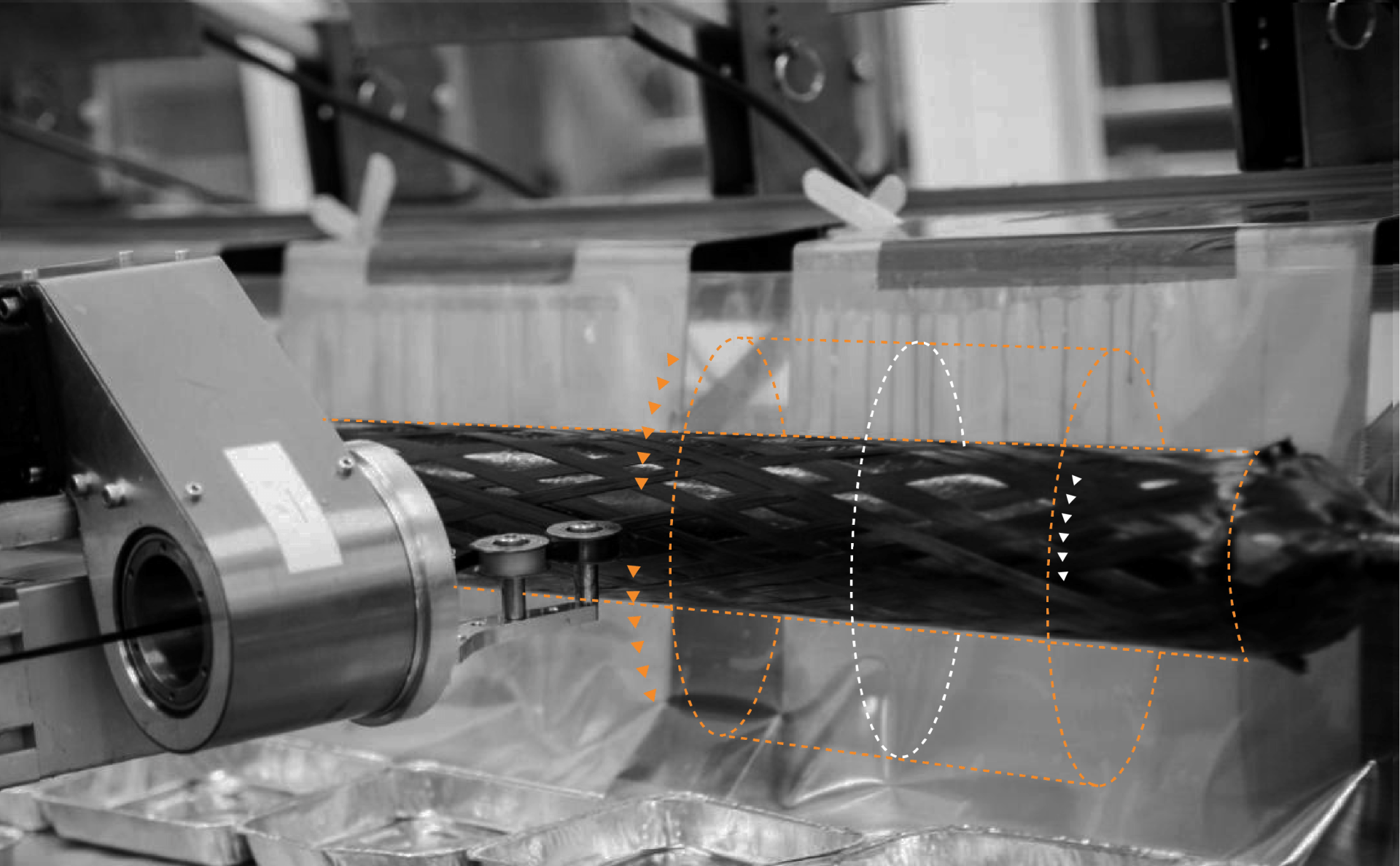

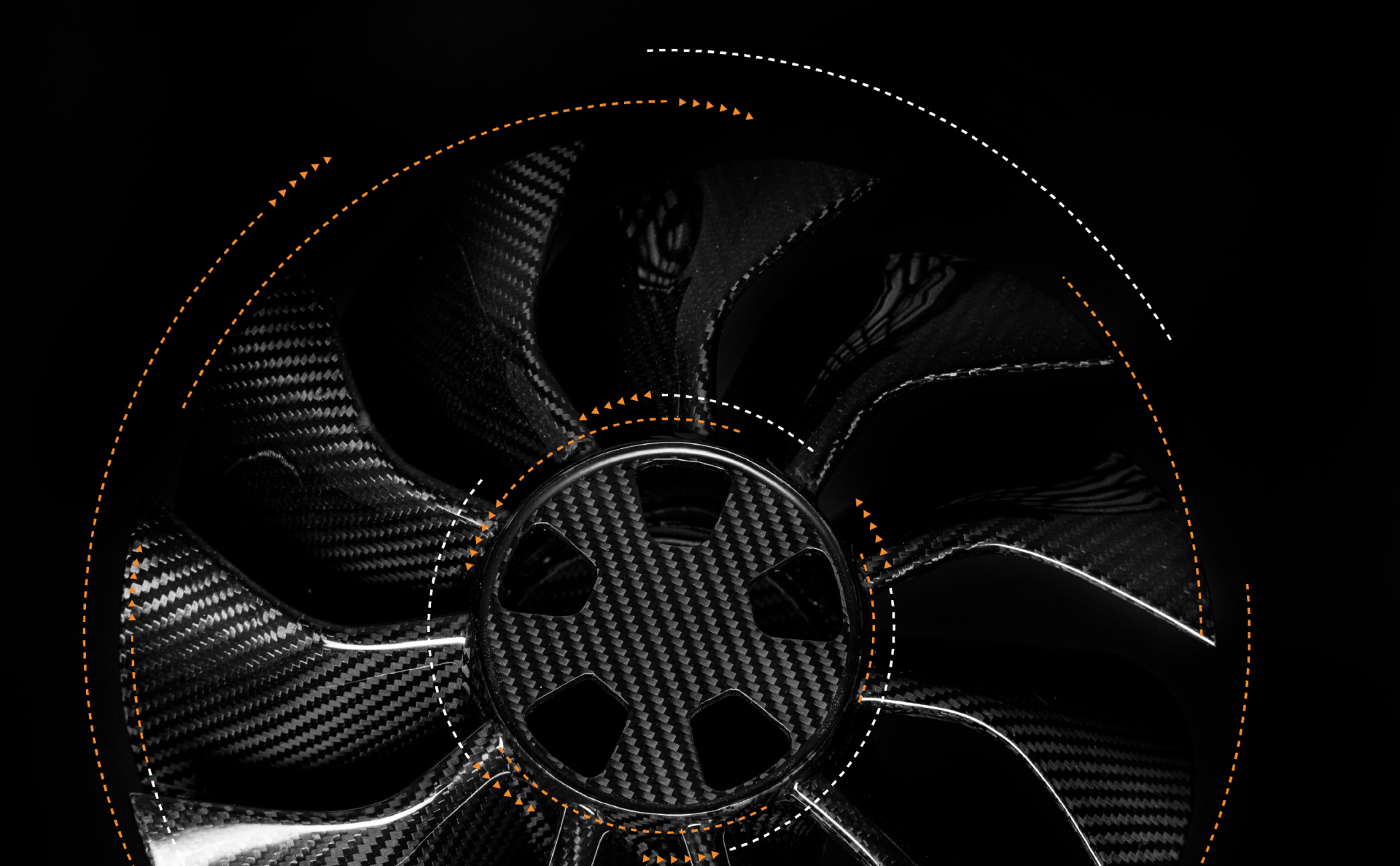

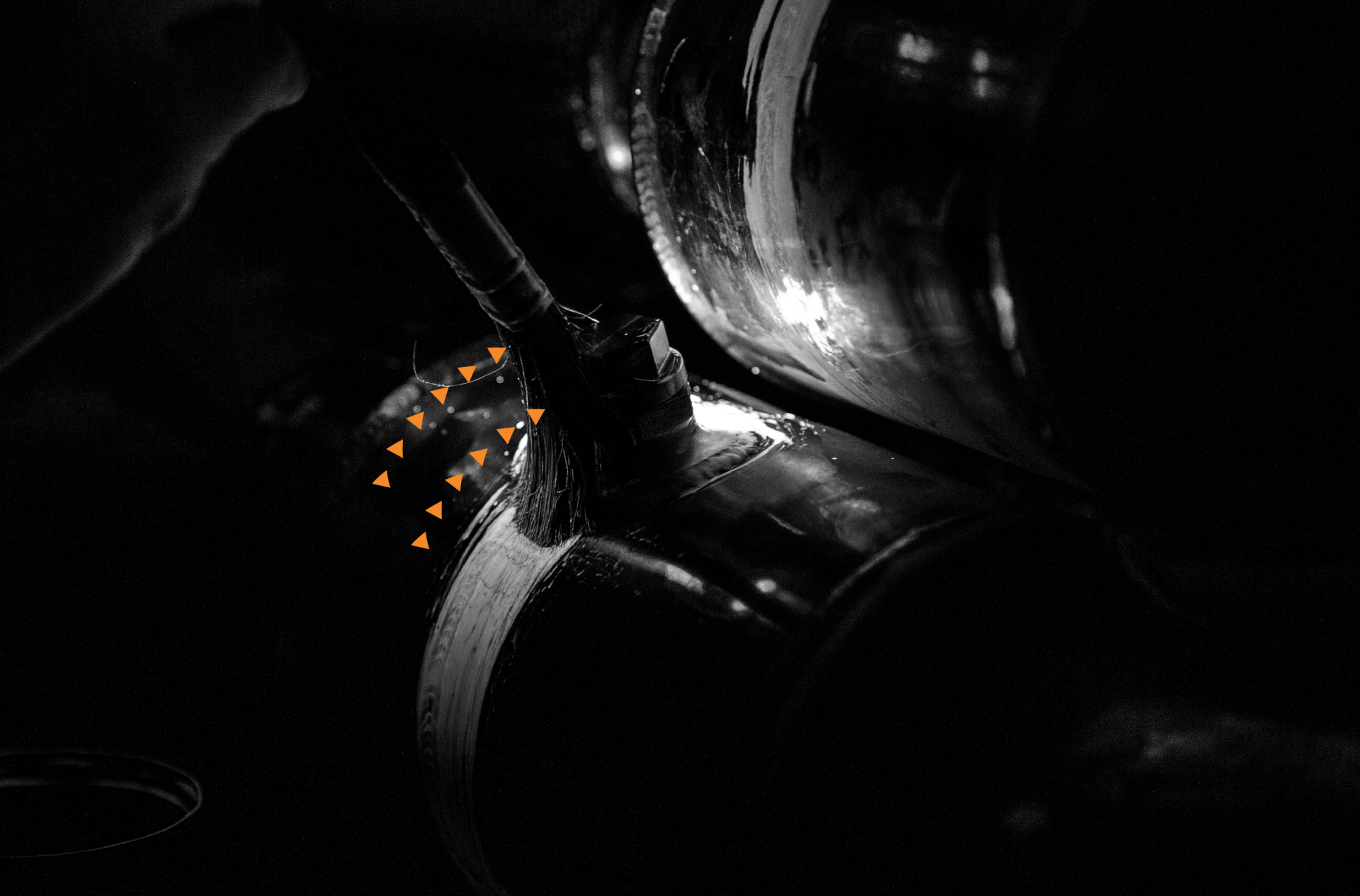

Lentus developing composite retention sleeves to support the electrification of the transport sector

We have developed high-speed optimised Carbon Fibre Reinforced Polymer (CFRP) sleeves for use in electric rotor applications